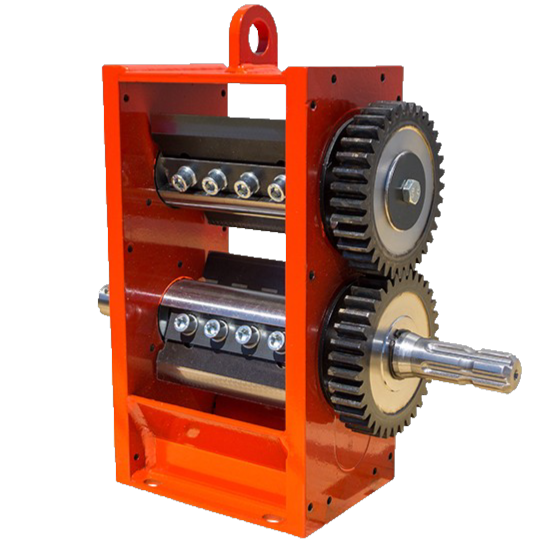

Chipping mechanism with a robust construction, welded from thick materials, designed for customer customization according to their own needs.

Drum cutting mechanisms for chippers are used to process wood waste, such as cuttings, branches, and tree trunks with a maximum diameter of 160 mm (circular shape) into various lengths depending on the model. All models of the mechanisms have through or threaded holes for mounting covers and the support frame. Each mechanism has an additional shaft under the pulley/flywheel, designed to lighten the load on the tractor and balance the operation of the device.

Cutting mechanisms are great for working with a tractor with a power take-off shaft, electric or combustion drive.

Cutting mechanisms are available in two knife arrangements:

4 or 6 knife arrangement (model: R-60, R-80, R-100)

6 or 8 knife arrangement (model: R-120, R-150, R-200)

The constructional elements of the chipper are laser cut. Then the body of the chipper is welded, providing much greater resistance to vibrations that occur during operation. As a result, the structure is stronger and more durable than in the case of bolted mechanisms. The welded body is machined on precise CNC machining centers, where bearing housings are made.

Thanks to this technology, concentricity is maintained, contributing to increased service life and proper device operation.

The cutting units are made of high-quality heat-treated steel and then machined on CNC lathes and milling machines.

The cutting knives are made of durable HARDOX TYPE 500 steel. The gears of the cutting mechanisms are induction hardened. In the R-120, R-150, and R-200 models, an expanding sleeve is used for positioning the cutting units, which also has a protective function in case of emergency overload. The complexity and multi-phase production process of chippers affects the high quality and reliability of the shredders.

| Number of Knives | 4 or 6 |

| Internal Width of the Mechanism (Knife Length) | 180mm |

| Knife Material | Hardox 500 |

| Knife Thickness | 8mm |

| Diameter of Gears | 150mm |

| Weight of the Machine | 55kg |

| Length of Chipped Wood | 4-knife arrangement 9-15cm |

| Length of Chipped Wood | 6-knife arrangement 5-10cm |

| Maximum Wood Diameter | 5.5cm |

| Recommended PTO Speed | 540rpm |

| Minimum/Recommended Power | 10-20 HP |

| Flywheel Shaft Diameter | Ø35mm |