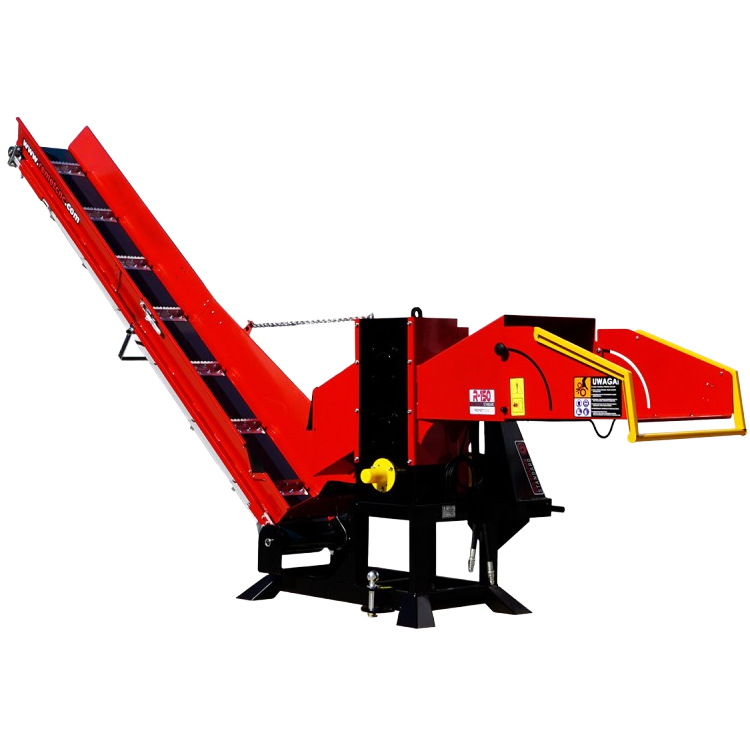

Chipper for standard use equipped with a conveyor for comfortable trailer loading.

Tractor-mounted chippers by DEMAVEX are divided into two categories based on the method of processing branches, tree trunks, and wood waste, such as firewood. The first category includes chippers for cutting wood with a maximum diameter of 160 mm into various lengths depending on the model. The second group includes chippers that process material with a maximum diameter of 120 mm into small chips. All chippers have a three-point hitch system for attachment to a tractor.

The structural elements of the chipper are laser cut. Then the chipper body is welded, providing much greater resistance to vibrations that occur during operation, making the construction more robust and durable than bolted mechanisms. The welded body is machined on precise CNC machining centers, where the bearings housings are produced.

Thanks to this technology, concentricity is maintained, contributing to increased lifespan and proper operation of the device.

The cutting mechanisms are made from high-quality heat-treated steel and subsequently machined on CNC lathes and milling machines.

The cutting knives are made of durable HARDOX 500 steel.

The gears of the cutting mechanisms are induction hardened.

To meet customer expectations, the designers created two series of cylindrical chippers, STANDARD and PROFESSIONAL. To increase efficiency and work comfort, tractor-mounted chippers are also available in versions with folding belt conveyors with hydraulic drive, which can work in two planes, longitudinal and transverse to the chipper.

STANDARD chippers are intended for private users who value not only quality but also the economic factor. Simple and robust construction ensures trouble-free operation and functionality.

For customers who want to use chippers industrially, the PROFESSIONAL line was created, characterized by, among other things: a frame made of steel profiles, a reinforced and extended intake hopper, rolling elements with increased load capacity, and increased operational comfort. These are just some of the differences between these two lines. Additionally, PROFESSIONAL chippers are equipped with an additional safety switch that can be connected to an existing PTO emergency stop module or another emergency switch mounted in the tractor powering the chipper.

| Usage | Standard |

| Number of knives | 6 or 8 |

| Internal width of the mechanism (knife length) | 220mm |

| Knife material | Hardox 500 |

| Gear diameter | 280mm |

| Machine weight | 415kg |

| Material removal method | conveyor 3m |

| Length of chipped wood | 8-knife version 5-10cm |

| Length of chipped wood | 6-knife version 12-18cm |

| Maximum machine capacity | 14m³/h |

| Maximum wood diameter | 13cm |

| Recommended PTO speed | 540 rpm |

| Mounting system | Three-point hitch |

| Minimum/recommended power | 45/80 hp |

| Flywheel shaft diameter | Ø45mm |

| Chipping method | coarse chips |

| Drive method | PTO (tractor) |

| Conveyor | 3m |